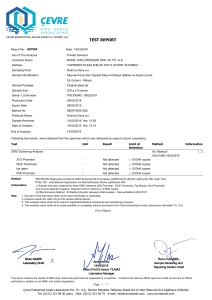

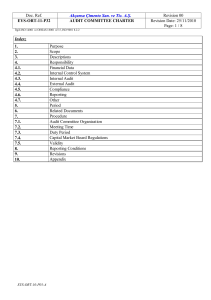

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Auditee :

AKKUS MODA TEKSTIL ORME SAN. VE TIC. A.S.

Audit Date From :

28/12/2016

Audit Date To :

28/12/2016

Expiry Date of the Audit :

Please refer to the producer profile in the BSCI platform

Auditing Company :

TUEV Rheinland

Auditor’s Name(s) :

Arda Karaoglan(Lead)

Auditing Branch (if applicable) :

TUV Rheinland Turkey

This is an extract of the on line Audit Report.The complete report is available in the BSCI Platform.

Access www.bsciplatform.org, for entitled users only.

All rights reserved. No part of this publication may be reproduced, translated, stored in a retrieval system, or transmitted, in any form or by any, means electronic,

mechanical, photocopying, recording or otherwise, be lent, re-sold, hired out or otherwise circulated without the FTA’s consent.

This is an extract of the BSCI Audit Report, which is available in the BSCI Platform. © Foreign Trade Association (FTA), 2013 - The English version is the legally binding One.

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 1/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Rating Definitions

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 2/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Main Auditee Information

Name of producer :

AKKUS MODA TEKSTIL ORME SAN. VE TIC. A.S.

DBID number :

365575

Audit ID :

72559

Address :

Merkez Mah. Günesli Yolu Cad. Yusuf Aga Sok. No:9/1-2 Yenibosna Istanbul

Province :

Istanbul

Management Representative :

Gulcin Firat Okmen

Contact person:

Country :

Turkey

Gulcin Firat Okmen

Sector :

Non-Food

Industry Type :

Textiles, clothing, leather

Product group :

Apparel

Product Type :

Knitted Outwear

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 3/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Audit Details

Audit Range :

Full Audit

Follow-up Audit

Audit Scope :

Main Auditee

Main Auditee & Farms

Audit Environment :

Industrial

Agricultural

Audit Announcement :

Fully-Announced

Fully-Unannounced

Random Unannounced Check (RUC) :

No

Audit extent (if applicable) :

none

Audit interferences or contingencies (if applicable) :

none

Overall rating :

Semi-Announced

B

Need of follow-up :

If YES, by :

Rating per Performance Area (PA)

PA 1

PA 2

PA 3

PA 4

PA 5

PA 6

PA 7

PA 8

PA 9

PA 10

PA 11

PA 12

PA 13

C

A

A

A

A

A

A

A

A

A

A

A

A

Executive summary of audit report

The audited factory was established in 2015 as a knitted outwear manufacturer for men and women with a total monthly capacity of 100.000 pcs per month.

The facility situated in a 7-story concrete building with a total production area of 1.800 square meters. The floor-wise description of the facility building was as

follows:

Basement -2nd floor: Restaurant

Basement -1st floor: Restaurant

Ground floor: Restaurant

1st floor: Meeting room and administrative offices

2nd floor: Sampling room, design, sample cutting and sample sewing sections.

3rd floor: Management offices and showroom

Roof floor: Canteen and sample warehouse

The process of sample sewing and sample cutting were done in-house. Main processes such as cutting, sewing, ironing, QC and packing processes were

subcontracted out to external facilities.

There were a total of 13 employees (8 male, 5 female) working in the factory. The youngest worker was 24 years old. Eating area is provided with a capacity of

30 seats and no dorms provided for workers. Food and transportation provided for free of charge. There was not a workers’ union available to employees in the

factory.

The factory adopted face scan attendance system to record employees' working hours. The regular working hours of all employees were from Monday to

Friday, from 8:00 a.m. to 6:15 p.m. with two times 15-minutes tea breaks at 10:00 a.m. and 4:00 p.m. respectively, and 45 minutes meal break at 12:30 p.m.

On Saturdays and Sundays were granted as weekly rest days.

Monthly wages were paid at monthly rate at latest on the 5th of each month through bank transfer.

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 4/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Ratings Summary

Auditee's background information

Auditee's name :

AKKUS MODA TEKSTIL ORME SAN. VE

TIC. A.S.

Legal status :

Private Company

Local Name :

AKKUS MODA TEKSTIL ORME SAN. VE

TIC. A.S.

Year in which the auditee was founded :

2015

Address :

Merkez Mah. Günesli Yolu Cad. Yusuf Aga

Sok. No:9/1-2 Yenibosna

Contact person (please select) :

Gulcin Firat Okmen

Province :

Istanbul

Contact's Email :

gulcin@akkustextile.com

City :

Istanbul

Auditee’s official language(s) for written

communications :

Turkish

Region :

Middle East/ North Africa

Other relevant languages for the

auditee :

N/A

Country :

Turkey

Website of auditee (if applicable) :

www.akkusmoda.com

GPS coordinates :

41.016049, 28.824081

Total turnover (in Euros) :

140000.00

Sector :

Non-Food

Of which exports % :

100.00

Industry :

Textiles, clothing, leather

Of which domestic market % :

0.00

Production volume :

300000

Production cost calculation :

Yes

Lost time injury calculation cost :

Yes

If other, please specify :

Product Group :

Apparel

If other, please specify :

Product Type :

Knitted Outwear

Auditee's employment structure at the time of the audit

Total number of workers :

13

Total number of workers in the production unit to be monitored (if applicable) :

0

MALE WORKERS

FEMALE WORKERS

Permanent workers

8

5

Temporary workers

0

0

In management positions

4

5

Apprentices

0

0

On probation

0

0

With disabilities

0

0

Migrants (national citizens)

0

0

Migrants (foreign citizens)

0

0

Workers on the permanent payroll

8

5

Production based workers

3

1

With shifts at night

0

0

Unionised

0

0

Pregnant

-

0

On maternity leave

-

0

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 5/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Finding Report

Performance Area 1 : Social Management System and Cascade Effect

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: C

Deadline date:28/02/2017

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Factory set and published own social compliance includes all BSCI requirements. Ms. Gulcin Firat Okmen is appointed senior management staff who

is responsible for BSCI Code 2.0 implementation. Regular meetings between HR, production manager and worker representatives held in regular

basis to avoid bottlenecks in the production. The factory maintained appropriate daily, weekly and monthly plan records of workforce, production rate,

work capacity.

Fabrika kendi sosyal uygunluk prosedürünü oluşturmuştur. Sayın Gulcin Firat Okmen BSCI Code 2.0 uygulamalarından sorumlu üst yönetici olarak

atanmıştır. Çalışanlar ve yönetimle düzenli olarak toplantı yapılmaktadır. Fabrikada uygun günlük, haftalık, aylık üretim kayıtları tutulmaktadır.

1.1 -

The factory has established detailed policies and procedures on BSCI Code of Conduct 2014 expectations, however following documentations were

missing and/or needs improvement.

a. Internal audits records and CAPAs were not documented.

b. Dates and revision numbers are missing in documentations.

c. Business partner assessment records and procedures were missing.

d. There were issues needs to be corrected in PA1, PA2, PA5, PA7.

Fabrikada BSCI Tedarikçi Kuralları 2014 gereksinimlerine göre detaylı politika ve prosedürler oluşturulmuş olmasına karşın aşıdaki bazı

dökümanların eksik ya da yetersiz olduğu gözlenmiştir.

a. İç denetim raporları ve DÖF'ler dökümante edilmemiştir.

b. Dökümantasyonlarda revizyon numaraları ve tarihler yer almamaktadır

c. İş ortakları değerlendirme kayıtları ve prosedurleri yoktur.

d. PA1, PA2, PA5 ve PA7 bölümünde iyileştirme gereken maddeler vardır.

1.3 -

There were no assessment criteria and procedure related social compliance findings for selecting subcontractors, suppliers and service provider's in

the facility. The factory did not monitor the subcontractors, suppliers and service provider’s social performance and did not maintain appropriate

records of subcontractors, suppliers and service providers commitment to social compliance.

Firmada fasonlar, tedarikçiler ve servis sağlayacılarının seçilmesinde sosyal uygunluk ile ilgili değerlendirme kriterleri ve prosedurleri

oluşturulmamıştır. Fabrika fasonlar, tedarikçiler ve servis sağlayıcılarının BSCI gereksinimleri uyarınca sosyal performansını denetlememektedir.

Buna ilişkin düzeltici önleyici faaliyet kayıtları görülememiştir.

Remarks from Auditee:

Performance Area 2 : Workers Involvement and Protection

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:28/02/2017

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Satisfactory evidence has showed that there are freely-elected worker representativ. It has been noted that the auditee has an effective grievance

mechanism; the mechanism consists of using suggestion boxes, worker representation, and an open door policy.

Elde edilen yeterli kanıtlara göre fabrikada özgürce çalışanlar tarafından seçilmiş bir işçi temsilcisi bulunmaktadır. Şikayet kutuları, işçi temsilcileri ve

açık kapı politikası gibi uygulamalar çalışanların kendilerini rahatça ifade etmelerini sağlamaktadır.

2.1 -

Two-way communication meetings between the employees and employer were not conducted to discuss about improving working conditions.

İşyerinin çalışma koşullarını iyileştirmeye yönelik çift-yönlü şikayet dinleme toplantılarının yapıldıgına dair kayıtlar gorulememistir.

Remarks from Auditee:

Performance Area 3 : The rights of Freedom of Association and Collective Bargaining

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Employees are free to join any union or association and management does not interfere or restrict workers choice of joining or forming any union or

association. Auditor note regarding N/A - marking for 3.3: There was no union established in the factory.

Çalışanların gruplaşma özgürlükleri fabrika yönetimi tarafından yasaklanmamaktadır. 3.3 maddesindeki N/A olarak işaretlenmesi için denetçi notu:

Firmada sendika bulunmamaktadır.

Remarks from Auditee:

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 6/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Performance Area 4 : No Discrimination

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

The factory has established written social procedures including anti-discrimination. Employees have been well trained on the procedures and there

was no discrimination in hiring, compensation, access to training, promotion, termination or retirement based on race, caste, national origin, religion,

age, disability, gender, marital status, sexual orientation, union membership or political affiliation. No discrimination in any aspect according to

interviews.

Fabrikada oluşturulmuş olan sosyal yönetim sistemi prosedürleri ayrımcılığa karşı politikayıda kapsamaktadır ve çalışanlara bu konu hakkında detaylı

bir eğitim verilmiştir. Buna ek olarak fabrikadaişe alımlarda, ödemelerde, eğitim haklarında, işten çıkarmalard yada emeklilik haklarında din, dil, ırk,

yaş, cinsiyet, engellilik durumu, evlilik durumu, sendika üyeliği ve ya politik görüş ayrılığı gibi sebeplerden dolayı ayrımcılık yapılmadı ğı görülmüştür.

Yapılan işçi görüşmelerinde firmada herhangi bir ayrımcılık olmadığı doğrulanmıştır.

Remarks from Auditee:

Performance Area 5 : Fair Remuneration

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Monthly wages were paid at latest on 5th of each month through bank transfer. All wages paid on-time and wage calculation was correcly done in the

factory. All employees received payslips as a confirmation of wage receipt. All employees have been provided with legally required rights: annual

leaves, sick leaves, overtime wages, retirement benefits and social insurance. At least the minimum wage (Net 1,300.99 TL) provided to all

employees.

Çalışanlara aylık ücretleri her ayın 5'inde banka yoluyla yapılmaktadır. Maaşlar zamanında yapılmakta olup, ücret hesaplamaları doğru olarak

yapılmaktadır. Çalışanlara aldıkları ücreti açıklayan maaş bordroları verilmektedir. Tüm çalışanlara yasal hakları: Yıllık izin, hastalık izni, fazla mesai

ödemeleri, emeklilik hakları ve sosyal sigorta hakkı eksiksiz sağlanmaktadır. Tüm çalışanlar en az asgari ücret (Net 1,300.99 TL) almaktadırlar.

Remarks from Auditee:

Performance Area 6 : Decent Working Hours

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Employees’ working hours were recorded by face scan attendance system for each time-in and time-out. Systematically working practices are

arranged for as follows for all workers: From Monday to Friday: From 08:00 to 18:15 including 15’ and 30’ tea breaks and 60’ lunch break = 45

hours/week. Saturdays and Sundays were granted as weekly rest day.

Fabrikada çalışanların giriş çıkış kayıtları yüz tarama sistemi ile kayıt altına alınmaktadır. Çalışaların düzenli çalışma saatleri; Pazartesi'nden

Cuma'ya; sabah 8:00 ile akşam 18:15 arasında 15' ve 30' iki çay molası ve öğlen 60' yemek molası =45 saat/hafta şeklindedir. Cumartesi ve

Pazar'ları haftalık tatil olarak belirlenmiştir.

Remarks from Auditee:

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 7/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Performance Area 7 : Occupational Health and Safety

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:28/02/2017

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Auditor note regarding N/A - marking for 7.24 : There is no dormitory onsite. Health & Safety policies were in place and trainings on policies were

provided regularly. Emergency action plan was documented and teams were established. Latest risk assessment was conducted in 2016 and

adequate precautions were taken. Fire extinguishers were placed and clearly marked in the production floor. Fire training and evacuation drills were

conducted twice a year. PPE (e.g. gloves, goggles, work clothes and so on) provided to employees for free of charge and usage was encouraged

through posters and H&S signs on the walls. Evacuation plans were corrected at each floor and reflect the actual set-up of the floor. Machines were

regularly inspected and with guards. Safety control reports for compressor and boiler was reviewed and found acceptable. General H&S environment

in the factory was good.

7.24 maddesi için denetçi notu: Firmada yatakhane olmadığı için bu madde N/A olarak işaretlenmiştir. ISG politikası detaylı bir şekilde oluşturulmuş

olup çalışanlara ISG konuları üzerine eğitim verilmiştir. Acil eylem planları dökümante edilmiş olup, ekipler oluşturulmuştur. Risk değerlendirmesi en

son 2016 yılında yapılmış olup, gerekli önlemler alınmıştır. Yangın söndürücüler önleri açık bir vaziyette işaretli olarak yer almaktadır. Yangın eğitimi

ve acil tahliye tatbikatları yılda 2 kere yapılmaktadır. Kişisel koruyucu ekipmanlar (ö.r. eldiven, gözlük, iş kıyafeti, vb.) çalışanlara ücretsiz olarak

sağlanmaktadır ve çalışanlara kullanımı işaretlemelerle vurgulanmaktadır. Acil tahliye planları tüm katlarda düzeltilmiş olup, fabrikanın mevcut

konumu yansıtmaktadır. Tüm makinalarda makina koruyucuları sağlanmıştır. Kompresör ve kazanın fenni muayenesi yapılmıştır ve sonuçlar

uygundur. ancak firmanın bu prensibe tam uyum sağlaması için aşağıdaki iyileştirmelerin yapılması gerekmektedir.

7.17 -

The factory management was provided the auditor with the safety inspection report for elevator being used in the factory however there were non

compliance issues in the report and its failed. According to Turkish Labor Health & Safety Regulation (7/7583) Article 207 &244 of Turkish Labor Law

6331.

Fabrikada asansörün fenni muayenesi yapılmış fakat fenni muayene raporunda uygunsuz maddelerin oldugu gozlenmiştir. Is saglıgı guvenligi

(7/7583) Madde 207&244 yonetmelik 6331.

Remarks from Auditee:

Performance Area 8 : No Child Labour

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Factory management follows own policy that ensures there are no under aged employees in production which was confirmed by documents review,

appearance and interview. Factory verifies the age proof documents and retains copies of these documents on appointment. According to the age

documentation of the employees no child labor was found and worker’s testimonies support documentary evidence of compliance.

Fabrikanın takip ettiği sosyal uygunluk gereksinimlerine göre çocuk işçi çalışan bulunmamaktadır. Ayrıca fabrikanın gerek döküman kontrollerinde

gerekse saha turunda yapılan gözlem sonucunda çocuk işçi çalışan olmadığı açık bir şekilde görülmüştür.

Remarks from Auditee:

Performance Area 9 : Special protection for young workers

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Auditor note regarding N/A marking for 9.6: There were no young employee in the facility. There were not any young workers in the facility. However,

factory have adequate policies and procedures that ensures a safe working condition to young employees.

9.6 maddesinin N/A olarak işaretlenmesi ile ilgili denetçi notu: Firmada genç çalışan bulunmamaktadır. İşyerinde genç işçi bulunmamaktadır. Ancak

fabrikada olası genç işçilere yönelik yeterli politika ve prosedürler oluşturulmuştur.

Remarks from Auditee:

Performance Area 10 : No Precarious Employment

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

All workers were local workers and were directly recruited by factory management. 5 (five) personnel files of workers were sampled and found that

the factory does not hold any original documents such as official ID cards, educational certificates, etc. Personnel files were documented with

worker’s job application, appointment letter, personal details and copies of age proof documents.

Tüm çalışanlar yerel çalışanlar olup belirsiz süreli sözleşmeleri mevcuttur. Seçilen 5 (bes) personelin incelenen özlük dosyalarında orjinal kimlik kartı,

pasaport vs. bulunmamaktadır. Personel dosyalarında iş tanımı, kimlik detayları bulunmaktadır.

Remarks from Auditee:

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 8/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Performance Area 11 : No Bonded Labour

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Auditor note regarding N/A - marking for 11.2 : There was no migrant workers in the factory. All employees were directly recruited by the factory

without requirement of any monetary deposits. Terms and conditions in personnel files did not reflect any coercion, limitation to the employee’s basic

right of freedom or forced labor of any kind beyond legal generally accepted obligations.

11.2 maddesindeki N/A olarak işaretlenmesi için denetçi notu: Firmada göçmen çalışan bulunmamaktadır. Fabrikanın çalışanlarının işe alımlarda

herhangi bir ücret talep etmediği doğacak zararlardan dolayı depozit alınmadığı görülmüştür. Sözleşmelerde yer alan maddelerde ve koşullarda

herhangi bir zorla çalıştırma durumu gözlenmemiştir.

Remarks from Auditee:

Performance Area 12 : Protection of the Environment

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Environmental police was in place. Wastes were collected and disposed through contracted and authorized companies and all required

environmental permits/ licenses were available in the factory.

Fabrikada çevre politikası vardır. Tüm atıklar lisanslı ve anlaşmalı firmalar tarafından toplanmakta ve bertaraf edilmektedir. Firmada çevre ile ilgili tüm

izin ve lisanslar mevcuttur.

Remarks from Auditee:

Performance Area 13 : Ethical Business Behaviour

Full Audit [Audit Id - 72559] Audit Date: 28/12/2016 PA Score: A

Deadline date:

GOOD PRACTICES:

AREAS OF IMPROVEMENT:

Ethical procedures were established under social management system, this also covered the risk assessment on corruption. The factory

management was cooperative and granted access to all documents, site tour and private worker interviews during the course of audit.

Etik prosedürler sosyal yönetim sistemi altında dökümante edilmiş olup, yolsuzluk risk değerlendirmesini içermektedir. Fabrika yönetimi denetim

sürecini desteklemiş olup, denetçinin dökümanları incelemesine, saha turu yapmasına ve istediği işçilerle özel görüşmesine izin vermiştir.

Remarks from Auditee:

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 9/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Summary

Audit Type

Date

Audit Id

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PA8

PA9

PA10

PA11

PA12

PA13

Overall Rating

Full Audit

28/12/2016

72559

C

A

A

A

A

A

A

A

A

A

A

A

A

B

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 10/11

Producer : AKKUS MODA TEKSTIL ORME SAN.

VE TIC. A.S.

DBID : 365575 and Audit Id : 72559

Audit Date : 28/12/2016

Audit Type : Full Audit

Producer Photos

External photo(s) of the production unit(s)

IMG_4148.JPG

Photo of fire safety equipment

IMG_4140.JPG

Photo of the inside of the main production hall

IMG_4143.JPG

Photo first aid facilities

IMG_4135.JPG

Photo of the canteen (if applicable)

IMG_4130.JPG

Photo of the sanitary facilities

IMG_4144.JPG

Photo of fire safety equipment

IMG_4131.JPG

Photo of the code of conduct on display

IMG_4136.JPG

Photo of the inside of the main production hall

IMG_4134.JPG

Photo of fire safety equipment

IMG_4132.JPG

Photo of the inside of the main production hall

IMG_4139.JPG

Photo of the inside of the main production hall

IMG_4145.JPG

Photo of fire safety equipment

IMG_4137.JPG

Photo of the inside of the main production hall

IMG_4141.JPG

Photo of the inside of the main production hall

IMG_4146.JPG

Created with EO.Pdf for .NET trial version. http://www.essentialobjects.com.

Page 11/11

![DOĞUŞ GAYRİMENKUL YATIRIM ORTAKLIĞI A.Ş./ DGGYO [] 04.04](http://s1.studylibtr.com/store/data/002924085_1-ab00325ab94ab150ff848dbcddc2054d-300x300.png)